纤维素纳米晶(CNC)具有可再生、生物相容好、无毒、可生物降解、机械性能优异、比表面积大、水分散性好等特性,在石油开采、聚合物复合材料增强、水凝胶、气凝胶、超级电容器、节能建筑、化妆品、造纸、涂料、液晶和废水处理等领域显示出广阔的前景(图1)。然而,CNC的亲水表面限制了其进一步应用。对CNC表面进行聚合物接枝不仅可以改变其表面的亲疏水性能,而且可以赋予CNC多种其它功能(电导率、pH 或温度响应性、反应性等)。其中,通过表面引发的原子转移自由基聚合(SI-ATRP)可以很好地控制CNC表面聚合物的接枝密度、接枝链长和末端接枝等,进一步拓展了纤维素纳米晶的应用领域。

图1. 纳米纤维素的广泛应用

华南师范大学张振副研究员和周国富教授、法国波尔多大学Gilles Sèbe教授以及西南大学黄进教授等人在Journal of Applied Polymer Science期刊发表了题为“Grafting polymers from cellulose nanocrystals via surface-initiated atom transfer radical polymerization”的综述文章,系统地阐述了近年来通过SI-ATRP对CNC表面进行聚合物接枝的调控和机制,包括接枝密度、接枝链长及接枝区域的调控;并对其在纳米复合材料用填料、刺激响应材料、载体剂和其它领域的应用进行了总结(图2)。最后,针对目前通过SI-ATRP在CNC表面接枝聚合物存在的问题,该综述进一步指出CNC表面接枝聚合物的面临的发展机遇和挑战。

图2. 通过SI-ATRP对CNC表面调控及其性能和应用示意图

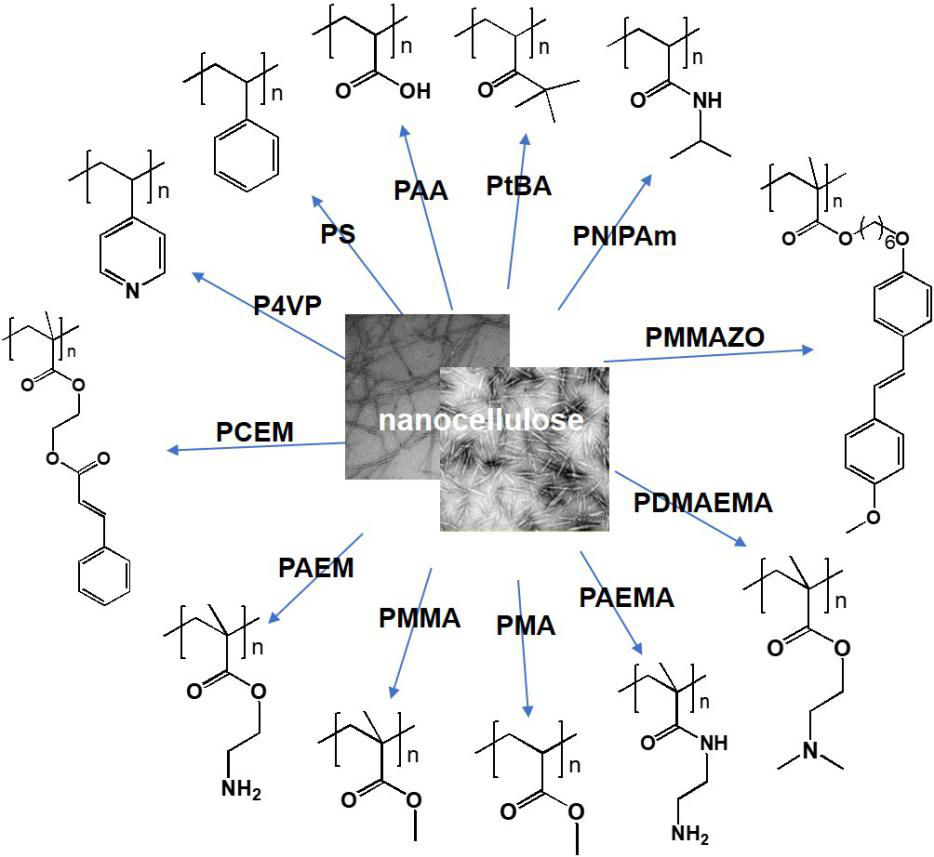

ATRP是一种活性聚合,可以通过调节单体和引发剂的比例以及单体转化率,有效调节聚合物的分子量。SI-ATRP作为一种“grafting from”的接枝聚合物方法,和“grafting to”的聚合物接枝方法相比,具有空间位阻小、接枝密度高的优点。由于SI-ATRP这种可控的接枝链长和接枝密度,被广泛用于各种基体或纳米材料的表面高分子接枝改性。目前已经通过SI-ATRP在纳米纤维素尤其是纤维素纳米晶上接枝了各种不同结构的高分子(图3),近年来在这一领域也发表了相关综述性文章,然而关于SI-ATRP对CNC表面接枝聚合物的接枝密度、接枝聚合物链长和接枝区域的精准调控机制讨论的综述还很少,该综述着重讨论了通过SI-ATRP在CNC表面接枝高分子调控的机制及其对性能的影响和相关应用。

图3.通过 SI-ATRP 在纳米纤维素表面上接枝的各种聚合物

接枝聚合物的密度:通过SI-ATRP在CNC表面接枝聚合物首先需要在CNC表面引入SI-ATRP的引发位点Br,目前一般采用BIBB的酰溴和CNC表面的羟基的酯化反应,CNC表面Br的含量很大程度上决定了接枝密度。然而这一过程仍然面临着BIBB利用率低、Br含量相对较低、有机溶剂用量多、CNC的内部结构容易遭到破坏等缺点。在SI-ATRP的过程中,引发效率也会影响接枝密度;由于SI-ATRP过程中空间位阻较小,一般CNC-Br的引发效率比较高。

图4. 通过SI-ATRP在CNC表面接枝聚合物的示意图

ATRP过程中需要无氧操作,而且需要大量的CuBr作为催化剂。ARGET ATRP是指在ATRP过程中加入过量的还原剂,和ATRP相比具有反应条件温和、不需要严格除氧和催化剂用量少等优点。通过对比SI-ATRP和SI-ARGET ATRP发现,在常规的SI-ATRP中,聚合过程中链增长速率相对较慢,CNC-Br上的Br引发位点几乎都能引发SI-ATRP,因此接枝密度相对较高(图5)。而在SI-ARGET ATRP中, CNC-Br上只有少部分Br被引发,聚合过程中链增长速率相对较快,较长的聚合物链屏蔽了周围Br的引发,因此CNC-Br的引发效率较低,接枝密度相对较低。

图5. Br-CNC的SI-ATRP和SI-ARGET ATRP接枝机理示意图

接枝聚合物的链长:SI-ATRP 最重要的优势之一是对接枝聚合物链长的准确控制,由于均相和非均相体系中的聚合机理可能不同,人们已经做了许多努力来证明SI-ATRP的反应活性。表征接枝聚合物的直接方法是通过 GPC 测量裂解的接枝聚合物的分子量和分散性。接枝聚合物通常需要在高温下用强酸或强碱进行裂解,为了克服这个问题,学者们通常会在体系中引入牺牲引发剂。如通过采用紫外光可裂解聚合物进行 SI-ATRP 接枝,证实了接枝聚合物和游离聚合物之间的等效性。紫外光可裂解带有 Br 引发位点的光连接剂,在牺牲引发剂的存在下进一步通过SI-ATRP接枝聚苯乙烯。结果发现接枝聚苯乙烯的分子量与游离 PS 的分子量非常吻合。由此说明,聚合物-g-CNC 中接枝聚合物的链长可以通过单体与牺牲引发剂的摩尔比或单体转化率进行调节。

CNC的末端聚合物接枝改性:通过控制聚合物在纳米粒子表面接枝的区域可以实现CNC表面的不对称接枝。例如通过硫酸水解等方法可获得两端带有不同的官能团的CNC,即非还原端带有羟基侧基,还原端带有醛基。通过对CNC的还原端进行区域选择性改性可实现CNC表面的不对称接枝。如图6所示,首先采用亚次氯酸钠(NaClO2)将CNC表面的醛基氧化为羧基,然后分别与乙二胺和2-溴异丁酸N-羟基琥珀酰亚胺酯反应,进而通过SI-ATRP,可以在CNC的还原端接枝不同的聚合物单体,使CNC的一端接枝上斑片状或多毛聚合物。通过TEM照片,可以观察到金纳米颗粒标记的斑块状的CNC,表明其表面聚合物的成功接枝。

图6.(a)通过SI-ATRP对CNC的还原端改性;(b)通过SI-ATRP对CNC进行表面均匀改性;(c)一端接枝聚合物并用金纳米粒子标记的斑片状CNC的TEM图像

性能与应用:该综述还进一步探索了利用SI-ATRP制备的聚合物接枝纤维素纳米晶Polymer-g-CNC的性能以及在纳米复合材料增强剂、刺激响应性复合材料等方面的应用。

总结与展望:由于CNC优异的性能,开发低成本、高性能的纤维素基可生物降解材料是替代化石基塑料的有前途的替代品。近年来,CNC生产已朝商业化方向发展。然而,CNC 的亲水表面和表面官能团缺乏(除了羟基)阻碍了它们更广泛的应用和商业化。在此背景下,通过聚合物接枝对 CNC 进行表面改性可用于调节其表面性质,并赋予 CNC 多种功能,可以进一步促进其在许多未开发领域的应用。总之,通过 SI-ATRP 从 CNC 接枝聚合物是一种非常有前途的调整纳米纤维素表面性质的方法。

论文下载链接:http://doi.org/10.1002/app.51458

作者信息:

Dr. Zhen Zhang is an Associated Researcher at South China Normal University (Guangzhou, China) since 2019. He received his Bachelor of Engineer degree in Polymers from East China University of Science and Technology (Shanghai, China) in 2009, Master of Science degrees in Materials from ECUST and Chemical Engineering from Chalmers University of Technology (Goteborg, Sweden) in 2012, and PhD degrees in Polymers from Bordeaux University (Bordeaux, France) and in Chemistry from University of Waterloo (Waterloo, Canada) in 2017, respectively. His research interests mainly focus on the preparation, surface modification and applications of nanocellulose.

张振副研究员,本科毕业于华东理工大学,硕士毕业于华东理工和瑞典查尔姆斯理工大学,博士毕业于加拿大滑铁卢大学和法国波尔多大学,2019年加入华南师范大学华南先进光电子研究院周国富教授团队,主要研究方向为纳米纤维素(纤维素纳米晶)的制备、改性和应用,Pickering乳液,相变材料等,目前已经在Chemical Engineering Journal, ACS Sustainable Chemistry & Engineering, Carbohydrate Polymers, Cellulose, Journal of Colloid and Interface Science, Advanced Sustainable Systems, ACS Applied Nano Materials和《化学进展》等期刊发表一作或通讯作者论文20余篇。

Gilles Sèbe is an Associate Professor at the University of Bordeaux in France, within the Laboratoire de Chimie des Polymères Organiques (LCPO). After receiving his Ph.D. degree in wood chemistry in 1996, he did a one-year post-doc at McMaster University in Hamilton (Canada), and then joined the BioComposites Center in Bangor (UK) for a two years period. In 2000, he was appointed at the University of Bordeaux, doing research and teaching on wood and biopolymers chemistry. His current research at the LCPO aims at developing novel nanocellulose-based functional materials, through the chemical tailoring of the nanocellulose surface.

Yelin Hou (候晔琳) recieved her bachelor''s degree of Light Chemical Engineering from Shaanxi University of Science and Technology. She will receive her master''s degree of light industry technology and engineering from Shaanxi University of Science and Technology, and she is now a PhD candidate at the doctoral school of Chemical Sciences in the University of Bordeaux under the supervison of Dr Gilles Sèbe. Her research interests mainly focus on cellulose nanocrystals and organic-inorganic nanocomposites.

Juan Wang (王娟) received her Bachelor degree in Material Chemistry from Qiuzhen College of Huzhou Normal College in 2020 (which is renamed to Huzhou College in 2021). She is currently an engineer in ScienceK Ltd. ScienceK (闪思科技 www.sciencek.com) is one of the leading pioneers in the commercial production, functionalization, and application of nanocellulose (especially cellulose nanocrystals, CNC) in China. 闪思科技ScienceK是中国纳米纤维素生产、改性和应用研发的先行者。

Prof. Jin Huang (黄进教授) obtained Ph.D degree in Wuhan University, and serves as the full-professor in Southwest University (China) and the director of “Chongqing Key Laboratory of Soft-Matter Material Chemistry and Function Manufacturing”. He carried out scientific research at Institute of Chemistry (Chinese Academy of Sciences), Wuhan University of Technology, Institut National Polytechnique de Grenoble, etc. His research focuses on "Polymer-Centered Soft-Matter Materials", "Sustainable Chemistry and Materials", "Flexible Materials and Devices", "Advanced Materials Manufacturing", etc. The research on "cellulose nanocrystals-based materials" has achieved great progress. He has published over 200 peer-reviewed papers, and edited 3 monographs and wrote 8 book chapters.

Prof. Guofu Zhou (周国富教授) received his Ph.D in Chongqing University, 1986. He served Philips Research Laboratories in the Netherlands as a senior scientist and principal scientist from 1995 to 2011. He is currently a Professor at South China Normal University (SCNU) in the field of micro/nano optoelectronic materials, devices and flat panel displays. He is also a Co-founder & Director of Electronic Paper Display Institute of SCNU, National Center for International Research on Green Optoelectronics and joint research labs of SCNU-TUE. He is leading several national research projects and Sino-Dutch joint projects.

- 吉林大学徐雁教授/法国科学院 Yoshiharu Nishiyama教授《ACS Nano》:首次实现纤维素纳米晶右旋光子薄膜 2025-12-19

- 华南师大张振 Small:纤维素纳米晶稳定皮克林乳液法制备高潜热、热致变色的相变材料微胶囊及其在智能涂料上的应用 2025-07-09

- 波尔多大学Gilles Sèbe、华南师大张振 Carbohydrate Polymers:皮克林乳液界面SI-ATRP制备两亲性纤维素纳米晶 2025-05-19

- 四川大学李建树教授/谢婧副研究员团队《Mater. Horiz.》:定制化聚合物盔甲增强骨关节炎治疗效果 2024-08-19

- 青科大张建明/宗鲁团队 ACS Mater. Lett.:聚电解质化纤维素纳米晶助力其再分散及高效湿气水收集 2024-02-18

- 离子催化中的“双刀流” - 钙钴双离子纤维基催化材料实现过一硫酸盐高效活化 2023-04-14