塑料

尤里卡-莫雷托(EUREKA–MORETTO)在K2010展上展出其PET干燥系统

2010-8-6 来源:中国聚合物网

关键词:PET干燥系统 K2010 尤里卡-莫雷托 EUREKA–MORETTO

2010-8-6 来源:中国聚合物网

关键词:PET干燥系统 K2010 尤里卡-莫雷托 EUREKA–MORETTO

The integrated FLOWMATIK controller is designed and programmed to detect each hopper’s capacity and the material’s bulk density, the desired resident time, temperature, and the air flow rate. “Once you have control over the process, the exact drying time needed can be established. All you have to enter is the material type and the desired throughput rate; the system will take care of the rest”, according to Renato Moretto. By tailoring airflow to the throughput rate, higher savings are obvious. His innovative ideas go even further: The FLOWMATIK Split system divides the PET to be dried first into a larger hopper at a relatively low temperature, then into a second, smaller hopper at the customary 180° C. The efficient approach of EUREKA is designed to reduce airflow needs by more than 50 percent. Research into greater efficiency and improved user benefits utilized computerized fluid-dynamic and thermo-dynamic simulation trials to analyze current leading hopper designs. Non-uniform flow through the hopper, combined with temperature gradients of up to 80° C (from centre to outside), have been identified. In addition, material can contain twice as much moisture as the average of the hopper in its entirety. The conclusion: given a nominal four-hour residence time in the hopper, some material exits in as little as 2.5 hours’ time.

Another processing benefit is that one dryer can be taken off-line, whilst a newly regenerated dryer (standard with the system) is installed as a replacement. In order to achieve not only a considerable reduction in energy use, more uniform heating and efficient regeneration at lower airflow rates are possible.

The FLOWMAX system can be utilized in a number of different configurations according to individual requirements: i.e. FLOWMAX UNI (a battery of X MAX units), Twin and Multi with X MAX dryers creates complete Uni and multi-hopper systems which are able to meet a wide range of needs in the feeding and drying with very low energy consumption. FLOWMAX UNI comprises a battery of X MAX units with a single hopper, enabling dehumidification of large quantities of raw materials – up to 8,000 kg/h. In fact, X MAX is a multi-tower system at constant performance. While one dryer is in regeneration, the other units continue operation until they, too, are submitted to regeneration – one after the other. Not only does this ensure a steady process, but also it guarantees the rotation of the X MAX units for regeneration which can be also in 72 hours or up to 100 between a cycle and the following one in the same drying tower.

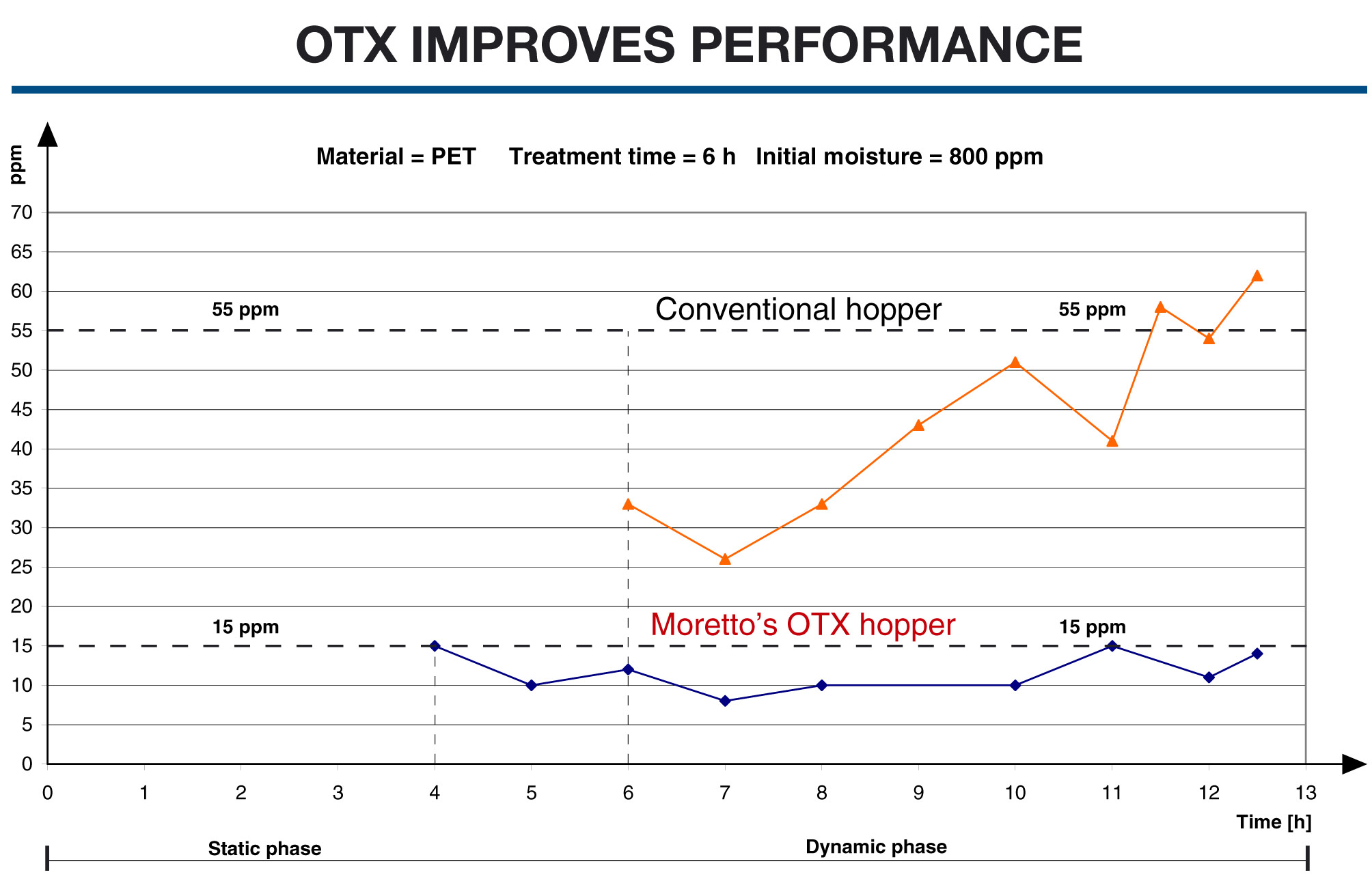

The redesigned state-of-the-art MORETTO OTX hopper with its new geometry solves the problem of the non-uniform fall flows of the granules, allowing to manage the process efficaciously. Also the air diffusion has been optimized eliminating the temperature differences. “Unlike the uncontrolled mixing occurring in conventional hoppers, our hopper achieves a much more uniform moisture ppm in less time”, explains Renato Moretto. To give an example, increased ppm control and uniformity results in a reduction in drying time from the typical six hours to an average of four hours and even less. In addition, drying temperatures can be reduced from 180° C to 175° C, also cutting air flow by up to 40 percent, whilst achieving 20 ppm final moisture (Figure 2). To summarize, by using the new MORETTO hopper, an identical throughput can accomplish a 30 percent decrease in drying time, 40 percent reduction in air flow requirement, and a 25 percent drop in hopper volume. Each hopper has its own heater, an airflow valve to allow for automatic variables, and a flowmeter, accommodating from 1000 to 10,000 liters, thus providing a flexible high volume, highly efficient system.

MORETTO S.p.A., among the global leaders in the field of plastics automation, designs, manufactures and distributes ancillary equipment for the plastics processing industry worldwide. Exactly 30 years ago the company was founded by its CEO, Renato Moretto. More than 200 employees work in the manufacturing and administrative facilities in Massanzago, near Padua in Italy. A dedicated and skilled sales network covers 52 countries, and 5 distribution centers represent the company in all continents. Renato Moretto strongly considers intellectual honesty, exceptional business ethics, absolute integrity, and technical competence to be the principal and essential elements of the professionalism of his company – OMS&P – Original MORETTO Systems & People.

注:本网转载内容均注明出处,转载是出于传递更多信息之目的,并不意味着赞同其观点或证实其内容的真实性。

(蓝剑)