化工

INCOE® introduces new Valve Gate solution and cost effective product improvements at K2010 in Düsseldorf, Germany

Rödermark, Germany- The hot runner system manufacturer INCOE® will be presenting several innovations at the 18th K trade fair in Düsseldorf, Germany, from October 27 through November 3, 2010. In addition to the new SoftGate® hot runner valve pin speed control, the areas of emphasis will include detailed improvements in the

Direct-Flo™ Gold hot runner program and the “Integrated Hot Runner System.”

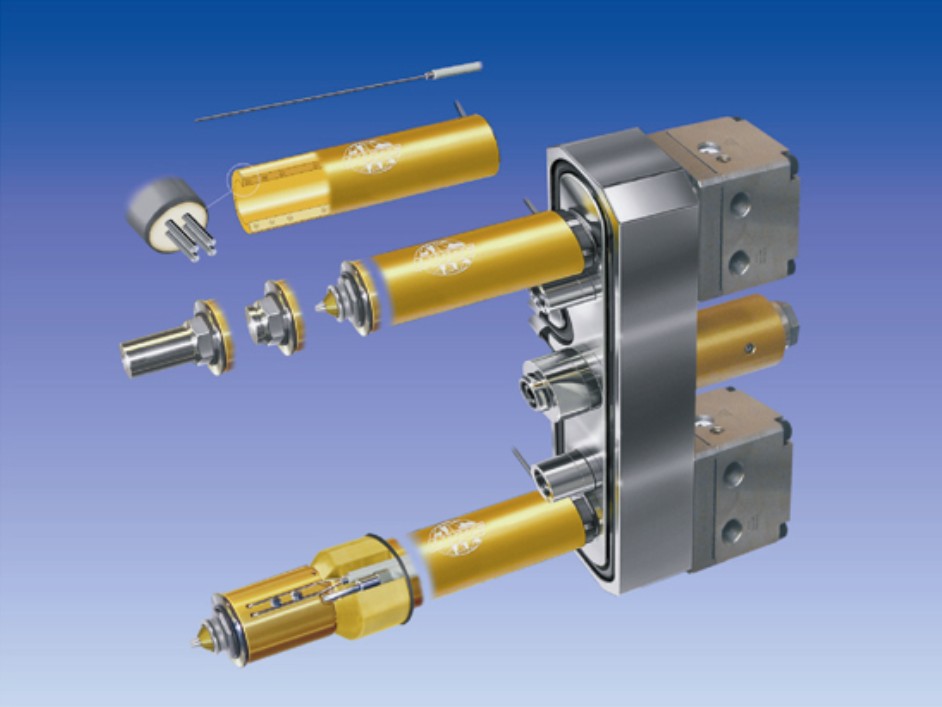

The latter of these provides the perfect solution for multi cavity moulds as a cost effective alternative to the Hot Half. This gives the mould maker a fully wired, plumbed and fully assembled hot runner system. Integrated systems are fixed to the mounting plate of the tool, permitting “in the machine” accessibility as well as complete freedom in designing the mould concept.

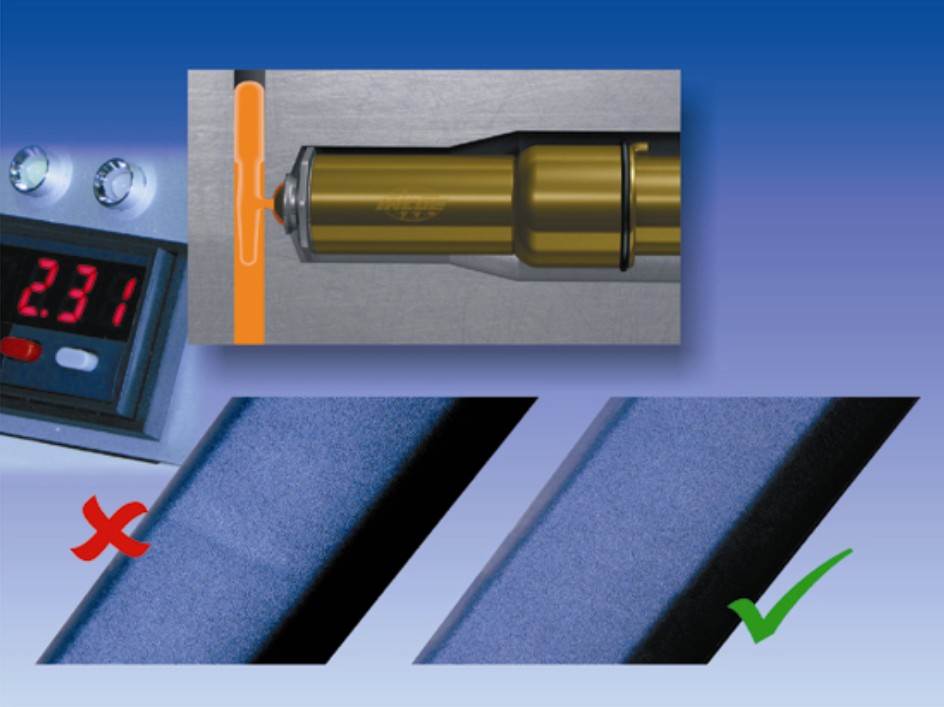

A highlight of innovative developments in the area of hot runner technology is INCOE®’s new patent pending SoftGate® hot runner valve pin speed control. With controlled opening of the valve gate nozzles, the process offers new reliability for surface quality in sequential injection moulding. SoftGate® is ideal for large parts that demand high quality cosmetic appearance. The technology can be applied in a wide range of applications. The process is also cost effective and can be retrofitted to existing systems.

New to the Direct-Flo™ Gold hot runner program are increased length heating elements. The new design reduces the area necessary to accommodate wires previously on the outside of the heater and along the length of the nozzle and is another innovation from INCOE® to improve efficiency and reliability. Also presented will be twin heater technology and temperature-controlled gate inserts for optimal gate quality.

Numerous processors will be presenting new, highly interesting applications and methods at their trade fair stands featuring these INCOE® technologies. To learn where these innovations will be presented please visit INCOE®, at Stand number 1B09 in Hall 1.

K2010 Press Release Image Descriptions

Image 1: The new patent pending SoftGate® valve pin speed control offers new process reliability for high-quality surfaces on large components produced using sequential injection moulding.

Image 2: As a cost effective alternative to the Hot Half, the Integrated Hot Runner and mounting plate offers complete design freedom in tool design.

Image 3: Direct-Flo™ Gold hot runner technology offers the utmost in integrated efficiency and reliability.

About INCOE® Corporation

Since 1958, INCOE® has engineered productivity built hot runner systems starting with their original patented design of the first commercial hot runner nozzle. Today, a wide range of nozzles and manifolds, pre-wired unitized systems, complete hot halves and advanced control technologies provide optimized systems suitable for appliances, automotive, caps/ closures, electronics, medical disposables, packaging , pharmaceutical and technical markets. A network of representatives in over 35 countries are supported by INCOE® facilities located in the United States, Germany,Brazil, China, Hong Kong and Singapore. Wherever your moulding operation is, INCOE® can support your business with complete hot runner systems engineered for your application… Right From The Start.

Since 1958, INCOE® has engineered productivity built hot runner systems starting with their original patented design of the first commercial hot runner nozzle. Today, a wide range of nozzles and manifolds, pre-wired unitized systems, complete hot halves and advanced control technologies provide optimized systems suitable for appliances, automotive, caps/ closures, electronics, medical disposables, packaging , pharmaceutical and technical markets. A network of representatives in over 35 countries are supported by INCOE® facilities located in the United States, Germany,Brazil, China, Hong Kong and Singapore. Wherever your moulding operation is, INCOE® can support your business with complete hot runner systems engineered for your application… Right From The Start.

注:本网转载内容均注明出处,转载是出于传递更多信息之目的,并不意味着赞同其观点或证实其内容的真实性。

(蓝剑)