Aluminoxane as Efficient Activator for Heterogeneous Ziegler-Natta catalyst for Propylene Polymerization at High Temperature

时间:2005-05-18

Qi Wanga,c, Zhenghua Zhanga, Kun Caob, Zhiqiang Fana Boping Liuc, Minoru Teranoc

a Department of Polymer Science & Engineering, Zhejiang University, China

b Department of Chemical Engineering, Zhejiang University, China

c School of Material Science, Japan Advanced Institute of Science & Technology, Japan

Industrial polymerization temperatures of MgCl2-supported Ziegler–Natta catalysts are around 70–80°C. The higher polymerization temperature (>80°C) is desired industrially to reduce the burden of removing the polymerization heat in the commercial plants. In recent years a new supercritical olefin polymerization technology was developed, which also required higher polymerization temperature (>90°C). However, both the activity and stereospecificity of MgCl2-supported Ziegler-Natta catalysts together with the molecular weight of resulting polymer decease at the temperature range over 80°C.

Several papers reported the propylene polymerization at the temperature higher than 70°C. Kojoh et al.1 reported that the activity and molecular weight dropped in the propylene polymerization at 100°C using MgCl2-TiCl4-dioctylphthalate catalyst in combination with alkylaluminum and diphenyldimethoxysilane. The activity and molecular weight obtained with Ali-Bu3 were higher than that with AlEt3. Hoeg and Liebman2 reported in propylene polymerization from 75 to 175°C using TiCl3-AlR3 catalyst system, the proportions of isotactic polymer with AlEt3 were higher than with Ali-Bu3. Zhong et al.3 investigated the effect of high polymerization temperature on the microstructure of isotactic polypropylene prepared by MgCl2-TiCl4-9,9-bis(methoxymethyl)fluorine activated by both Et3Al and i- Bu3Al without external donor.

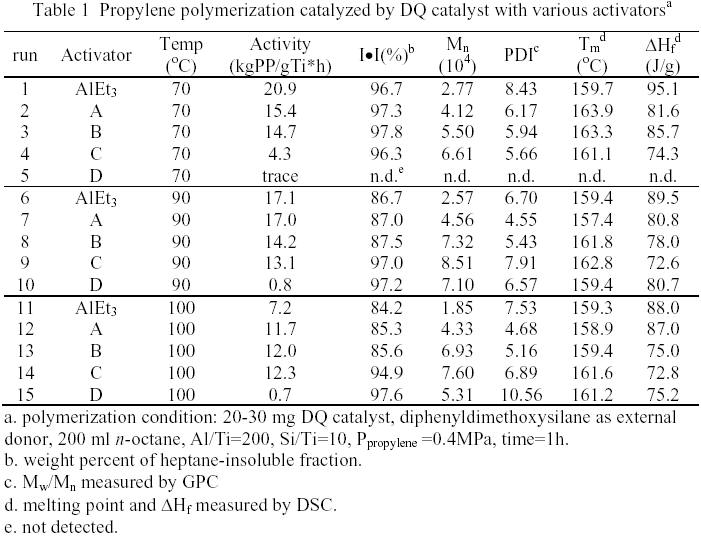

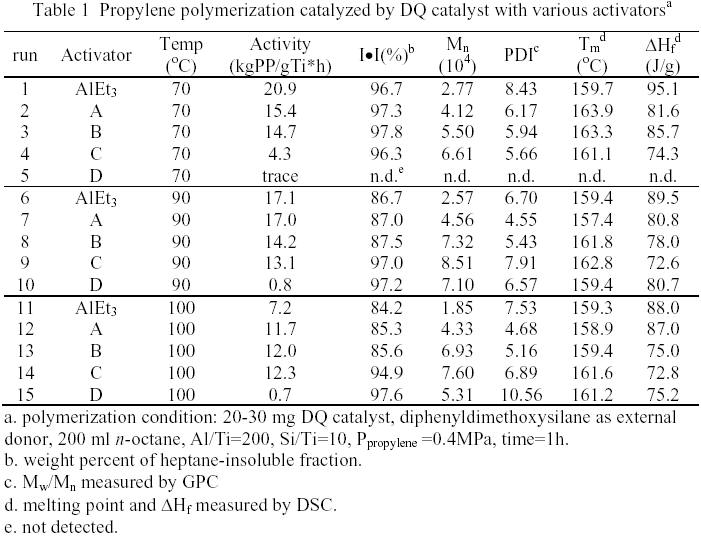

In this paper, various ethylaluminoxanes (EAO) were used as cocatalyst with commercial DQ catalyst (Sinopec, China) for propylene polymerization at temperature ranging from 70°C to 100 °C.

Four aluminoxanes were prepared by the reaction between Et3Al and water under different molar ratio, ranging from 2/1 to 10/9. As the ratio of Et3Al/water increased, various EAOs with different oligomeric degree can be obtained.

When propylene polymerization was carried out at 70°C, activity obtained with AlEt3 was higher than that with EAOs and isotacticity indexes of polymer prepared by different activators are similar. But the polymers obtained with EAOs have higher molecular weight than that with AlEt3. When polymerization temperature was increased up to 90°C, the activity with AlEt3 was close to that with EAOs and the molecular weight of polymers prepared by EAOs were much higher than that by AlEt3. The fraction of heptane-insoluble polymer prepared by AlEt3 was lower than 90%, while the same fraction of polymer prepared by activators C and D were as high as 97%. At 100°C, EAOs offer not only the higher activity but also the higher molecular weight and isotacticity than AlEt3.

In conclusion, EAOs are efficient activators for propylene polymerization at high temperature, which can produce polypropylenes with good activity and high molecular weight.

Reference

1. Kojoh, S.; Kioka, M.; Kashiwa, N. Eur Polym J 1999,35,751.

2. Boor, J., Jr. Ziegler–Natta Catalysts and Polymerizations; Chemical Industrial Press: Beijing, 1986; pp. 178–181.

3. Zhong, C.H., Gao, M.Z., Mao, B.Q. J. Appl. Polym. Sci. 2003,90,3980.

论文来源:Asia Polymer Symposium(APOSYM/2004)October 10-16