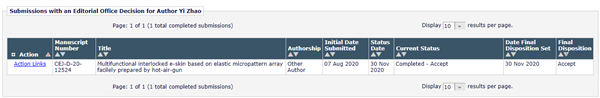

Congratulations to Zhang Yajie for paper on the preparation of elastomer surface micropatterns for multifunctional electronic skin by hot air gun has been accepted by Chemical Engineering Journal

Chemical Engineering Journal is one of the most influential journals in the chemical industry. As one of the SCI journals, its impact factor is 10.625. Electronic skin (e-skin) based on elastic piezoresistive sensor is considered to be one of the most important components for future wearable electronic devices, whose performances can be substantially improved by shaping patterned surface. However, most patterned surfaces are generally fabricated via some tedious methods. Obviously, it is still a huge challenge to realize high sensing performance via facile fabrication process. Here, an efficient but facile method named hot-air-gun assisted preparation is proposed, which enable quasi-hemispherical micropatterned array to be directly fabricated on the single-walled carbon nanotubes (SWCNTs)/thermoplastic polyurethane (TPU) film. The interlocked micropatterns can significantly improve the sensing performance of the as-prepared e-skin based on such micropatterned film, endowing it with very fast response time (<46 ms), wide working range (0.055-254.8 kPa) and excellent durability (>20000 cycles). Interestingly, the interlocked e-skin exhibits multifunction to simultaneously discriminate pressure-temperature stimuli. Moreover, it can monitor a variety of human physiological signals (e.g., arterial pulse waveform, voice recognition and human breathing behavior), indicating a promising application in human-machine interaction. Furthermore, the as-prepared interlocked e-skin could be connected to a wireless transmitter for wireless monitoring respiratory rates. Considering the facile preparation process and the low-cost raw materials, this approach can be easily scaled up for practical production.