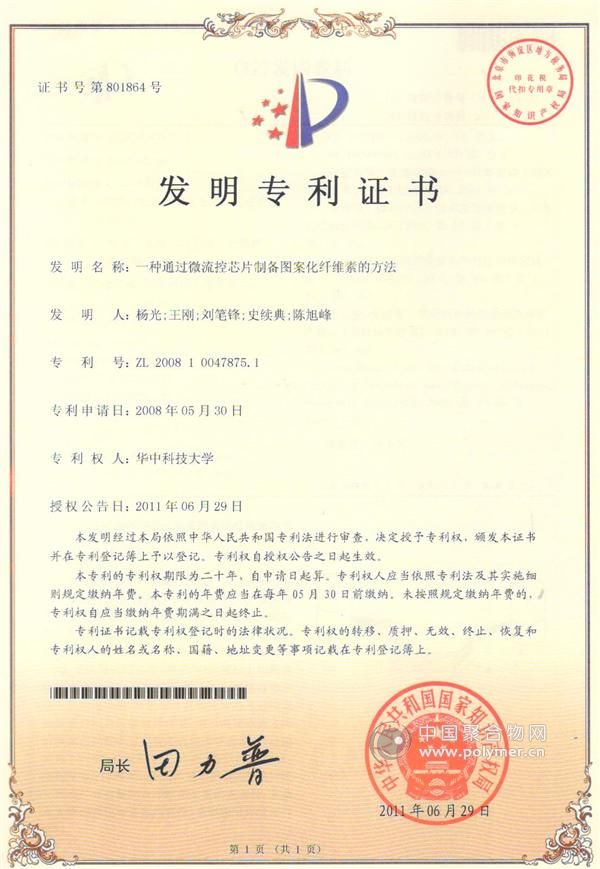

inventor/creator:杨 光,王刚,刘笔锋,史续典,陈旭峰

Paten number/application number:ZL 200810047875.1

application/authorized announcemen date:2011-3-24

brief introduction:

本发明提供了一种通过微流控芯片制备图案化纤维素的方法,按照以下步骤进行:(1)依据预定图案制作阳膜;(2)制备与阳膜图案相匹配的聚二甲基硅氧烷(PDMS)模块;(3)在PDMS模块上打孔,将洁净的载玻片压紧于PDMS模块有图案的一面,形成微流控芯片,其中PDMS模块上的图案化管道通过孔与外界相连通;(4)在两储液槽中装入细菌培养液,利用导管将微流控芯片的图案化管道分别与两储液槽连通,调节两储液槽之间的液面差控制图案化管道内的液体流速,其液面差为1-20cm,培养5-20天,揭开PDMS模块,得到图案化纤维素。采用本发明制得的细菌纤维素材料具有微观的有序性和宏观的图案性,并兼有生物相容性和生态相容性,是理想的环境友好材料。

ABSTRACT:

NOVELTY - Patterning cellulose is prepared by perforating polydimethyl silicone (PDMS) module matching with the anode film patterns; placing bacterial culture solution to liquid tanks and culturing 5-20 days; and removing the PDMS module to obtain the patterning cellulose. The PDMS is perforated by compressing a clean glass slide on one surface of the PDMS module having the patterns to form the microfluidic chip.

USE - Method for preparing patterning cellulose (claimed).

ADVANTAGE - The prepared bacteria cellulose material comprises microcosmic sequence and macroscopic patterning performance, and biocompatibility and ecology compatibility; and is perfect environment-friendly material.