Thermoplastic Polyester Elastomer Nanocomposites Filled with Graphene: Mechanical and Viscoelastic Properties

writer:Yaxin Qiu, Jun Wang, Defeng Wu, Zhifeng Wang, Ming Zhang, Ye Yao, Nengxin Wei

keywords:Polymer-matrix composites (PMCs); B. Mechanical properties; B. Creep; C. Modelling

source:期刊

specific source:Composites Science & Technology

Issue time:2016年

Composites Science & Technology, 2016, 132C, 108-115.

ABSTRACT:

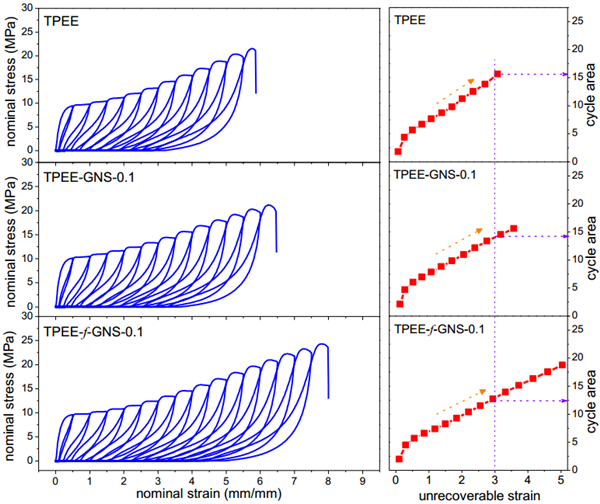

Graphene nanosheets (GNS) with and without

surface functionalization were used as the reinforcements to prepared the composites

with thermoplastic polyester elastomer (TPEE) by melting mixing. The results

show that the presence of GNS improves modulus, yield

and tensile strengths of TPEE, and the surface functionalization of GNS further

improves its reinforcing effect because of enhanced interfacial interactions.

However, the elongation levels also increase in the presence of GNS, which indicates

the increased elastoplasticity and

viscoplasticity of system. This is because the discrete hard poly(butylene terephthalate) domains of TPEE are

enriched on the surface of GNS and form ‘ball bearing’ structure in composites,

leading to increased deformation ability of soft continuous poly(tetramethylene glycol) of TPEE during large-scale

deformation. Thus, the composites show more amounts of tensile cycles with

shorter true strain plateau associated with onset of chain disentangling during

cyclic tensile tests. This ‘bearing ball’ effect, however, is not evident in

small-scale viscoelastic deformation because the presence of GNS restrains

creep of TPEE. In this case, the

impeding effect of GNS on the deformation of TPEE chain

coils is the dominant role. This work provides useful information on structure

design and control of the GNS filled thermoplastic elastomer composites.

PDF DOWNLOADED:

http://www.sciencedirect.com/science/article/pii/S0266353816303049