Springer-Nature旗下《Advanced Composites and Hybrid Materials》期刊第5期论文正式出版

https://link.springer.com/journal/42114/2/1

敬请各位专家学者多投稿,审稿,多浏览,下载和引用本期刊论文,也敬请您多提宝贵意见,以便我们后期进一步优化和改进本期刊质量,感谢您的大力支持!

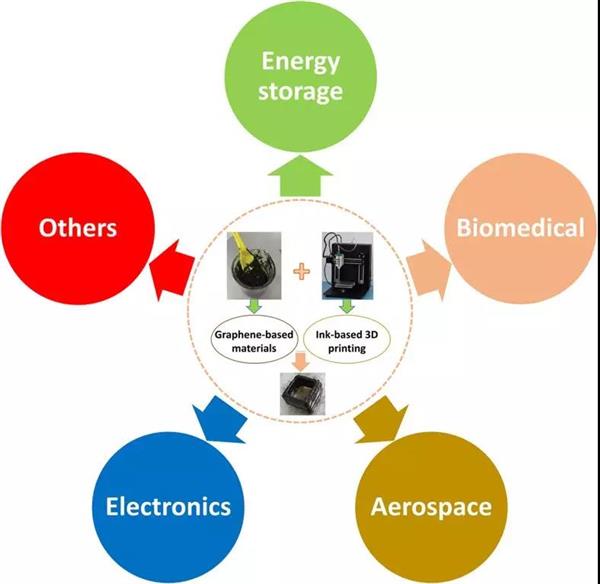

Ink-based 3D printing technologies for graphene-based materials: a review

Jingfeng Wang, Yuyan Liu*, Zhimin Fan, Wu Wang, Bin Wang, Zhanhu Guo*

Advanced Composites and Hybrid Materials, 2018, 2: 1-33

DOI: 10.1007/s42114-018-0067-9

Abstract: 3D printing (3DP) including light-based 3DP and ink-based 3DP is a rapidly developing technology, which has received much attention of late. Light-based 3DP provides higher feature resolution, but the appropriate materials are limited. Ink-based 3DP is compatible with numerous types of materials, which can be prepared into printable inks and thus has more potential to find novel applications. Graphene-based materials have been extensively investigated in ink-based 3DP owing to their unique properties, such as high conductivity and superior mechanical flexibility. The objects from graphene-based materials via various ink-based 3DP have been reported in many fields, such as biomedical engineering and renewable energy. Still, some practical difficulties, such as the efficiency, cost, and the feasibility of mass production, have restricted it from widespread adoption by most industries. Therefore, to deal with challenges and provide new ideas for related research work, it is critical and essential to understand the ink-based 3DP using graphene-based materials. Here, we review the recent advances of ink-based 3DP of graphene-based materials. We introduce the basic properties and preparation methods of graphene, some promising ink-based 3DP, such as inkjet printing technology, direct-write assembly, and fused deposition modeling and their characteristics. The formation methodology of graphene-based materials, the performance of the as-printed architecture, and their potential applications are emphasized. We also discuss the challenges, research directions, and future trends of ink-based 3D printed graphene-based materials.

Inorganic-organic hybrid materials and their adsorbent properties

Asgar Kayan*

Advanced Composites and Hybrid Materials, 2018, 2: 34–45

DOI: 10.1007/s42114-018-0073-y

Abstract: Owing to their unique chemical and physical properties, inorganic-organic hybrid materials have been used in many application fields. In this paper, I have summarized the synthesis and characterization of various inorganic-organic hybrid materials with representative examples from my previous studies. These hybrid materials were used as adsorbents in heavy metal adsorption processes in order to solve metal pollution which is one of the most important environmental problems in the world. This review highlights the operation conditions such as pH, required dose, initial concentration, temperature, and treatment performance. Also, adsorption isotherms and adsorption kinetics are reviewed. This knowledge will provide the basis for the researchers who seek the new synthesis and application of hybrid materials in the future.

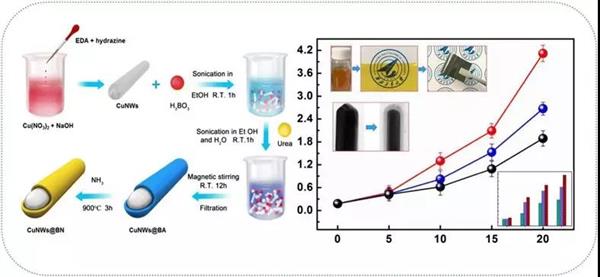

Use of BN-coated copper nanowires in nanocomposites with enhanced thermal conductivity and electrical insulation

Yongcun Zhou*, Feng Liu, ChiaYun Chen*

Advanced Composites and Hybrid Materials, 2018, 2: 46-50

DOI: 10.1007/s42114-019-00077-9

Abstract: Copper nanowires (CuNWs), as one-dimensional nanostructures, could be highly helpful as thermal management tools because of inherent thermal conductivity, high aspect ratio, and low cost. In this study, boron nitride-coated copper nanowires (CuNWs@BN) were successfully synthesized by an amenable and rapid technique and incorporated into synthetic polyimide (PI) to increase thermal conductivity while providing electrical insulation to nanocomposites. Maximal thermal conductivity in CuNWs@BN/PI composites containing fillers loading up to 20% volume rose to 4.12 W/mK, indicating an amelioration of 23 times in comparison with that of pure PI, while volume resistivity remained greater than 4.8 × 1013 Ω cm. Such nanocomposites with high thermal conductivity and electrical insulation could constitute important tools for thermal management.

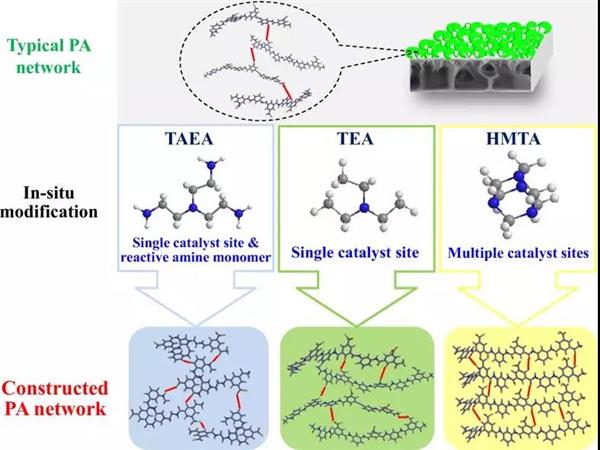

Developing high-performance thin-film composite forward osmosis membranes by various tertiary amine catalysts for desalination

Liang Shen, Lian Tian, Jian Zuo, Xuan Zhang, Shipeng Sun, Yan Wang*

Advanced Composites and Hybrid Materials, 2018, 2: 51–69

DOI: 10.1007/s42114-018-0070-1

Abstract: A desirable membrane with high separation performance, excellent antifouling properties, and chemical stability is important to the advance of forward osmosis (FO) technology in the wastewater treatment and desalination processes. In this work, three different tertiary amines, i.e., tri-ethylamine (TEA), tris(2-aminoethyl) amine (TAEA), and hexamethylenetetramine (HMTA), are employed as catalysts to accelerate the interfacial polymerization (IP) reaction for constructing the PA layer with optimized properties and performance of the resulting membranes. For the first time, the effect of different tertiary amines on the microstructure, morphology, and surface properties of formed PA layers, as well as the separation performance, fouling, and chemical resistance of the resulting TFC membranes, are studied systematically with various characterization techniques. As compared with the control membrane, modified membranes exhibit obviously improved separation performance and greater potential in the desalination process. Furthermore, modified membranes also exhibit improved fouling resistance and chemical stability. Therefore, the tertiary amine modification of TFC membranes may shed a new light for their future applications in harsh conditions.

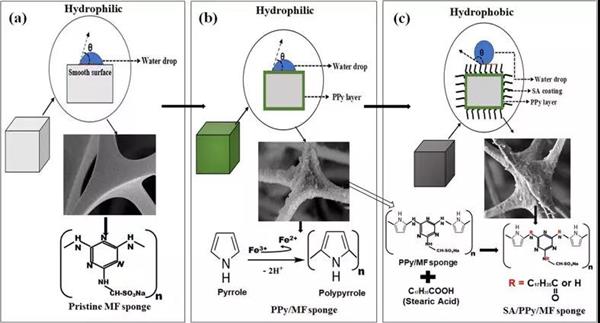

Stearic acid treated polypyrrole-encapsulated melamine formaldehyde superhydrophobic sponge for oil recovery

Love Dashairya, Anurag Sahu, Partha Saha*

Advanced Composites and Hybrid Materials, 2018, 2: 70–82

DOI: 10.1007/s42114-019-00084-w

Abstract: Oil spillage poses a serious threat to the marine ecosystem and the environment. This has led to an increasing demand for oil recovery and the quest for effective hydrophobic/oleophilic sorbents for oil-water separation. Herein, we developed polypyrrole (PPy) encapsulated melamine formaldehyde (MF) sponge treated with stearic acid (SA) to obtain a superhydrophobic SA/PPy/MF sponge. The SA/PPy/MF sponge characterized by X-ray diffraction, Fourier transform infrared spectroscopy, and field emission scanning electron microscopy shows that smooth struts of MF sponge get covered with PPy and further SA treatment affords an increased surface roughness and superhydrophobicity which is completely absent in the case of pristine MF sponge treated with either PPy or SA itself. The SA/PPy/MF sponge exhibits contact angles of ~ 170° and 0° by a sessile water and oil droplet on the sponge surface, respectively. Importantly, the SA/PPy/MF sponge demonstrated excellent superhydrophobicity over the entire pH range with absorption capacities reaching up to ~ 70–90 times for various oils from oil-water mixtures

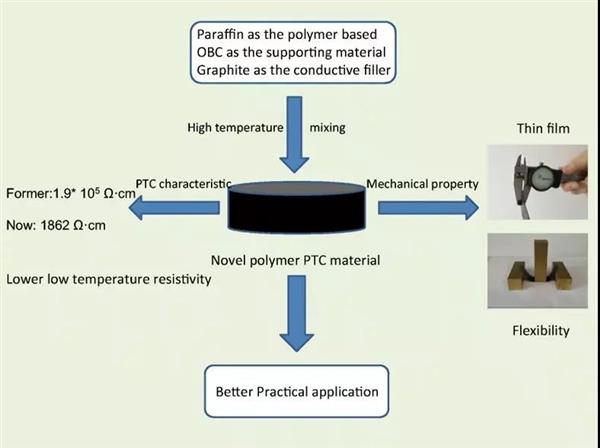

A novel flexible room temperature positive temperature coefficient material for thermal management

RuoJiang Wang, WenLong Cheng*

Advanced Composites and Hybrid Materials, 2018, 2: 83–92

DOI: 10.1007/s42114-019-00081-z

Abst: ractIn order to solve the installation application problem of positive temperature coefficient (PTC) materials in the field of thermal management for electronic devices and energy conversion system, a novel flexible thin film room temperature polymer PTC material is prepared and studied in this paper. The material is prepared by mixing graphite powder (GP) in paraffin/olefin block copolymer (OBC) in which OBC provides flexibility as a supporting material. Besides, the PTC characteristics and mechanical properties of the material are studied experimentally. It is found that the prepared composites have good PTC characteristics and flexibility. The measuring results show that flexibility of the novel PTC material is optimal when the content of graphite powder is 40% and mass proportion of OBC/paraffin is 30:70; at this time, the PTC intensity of the material can reach 2.9 and low temperature resistivity of the material is about 1800 Ω?cm. Meanwhile, the novel PTC material is compared with the conventional PTC material through various experiments. It is found that the novel PTC material prepared in this paper has better performance than the conventional PTC material in many aspects, and has better prospect and practical value.

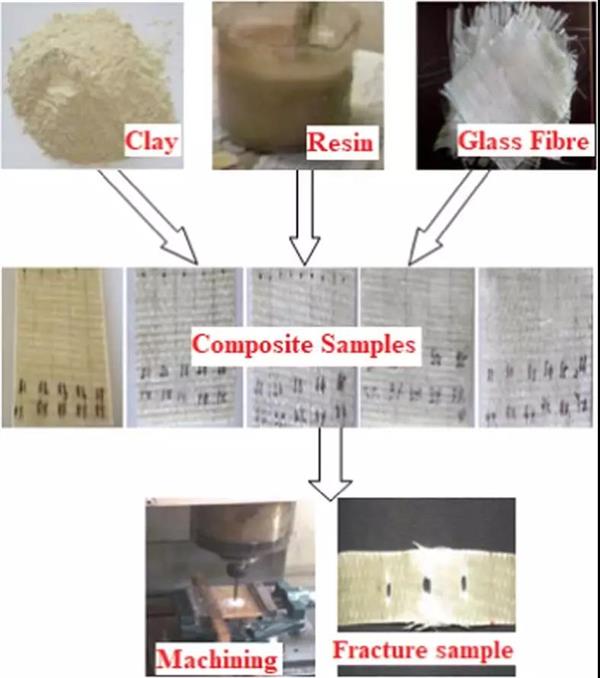

Experimental investigation of mechanical and machining parameters of hybrid nanoclay glass fiber-reinforced polyester composites

P. Prabhu*, S. Mohamed Iqbal, A. Balaji, B. Karthikeyan

Advanced Composites and Hybrid Materials, 2018, 2: 93–101

DOI: 10.1007/s42114-018-0065-y

Abstract: In this work, the effect of nanoclay addition to glass fiber-reinforced polyester composites is studied. The pristine glass fiber-reinforced polyester composites (i.e., staking sequence, kind of fabric used, etc.) and hybrid nanoclay in varying weight fraction (0, 1, 2, 3, 4 and 5 wt%) and glass fiber-reinforced polyester composite is prepared by vacuum-assisted resin infusion technique. Fracture toughness studies are done to analyze the critical stress intensity factor and critical strain energy release rate. The optimum mechanical properties are obtained for hybrid nanoclay glass fiber-reinforced polyester composites with clay content of 3 wt%. This paper also deals with the study of optimizing the cutting parameters (Cutting speed and feed rate) to obtain maximum mechanical properties in hybrid nanoclay glass fiber-reinforced polyester composites during drilling process. It has been found that the torque is unaffected with increase in cutting speed. On contrast with increase in feed and nanoclay weight fraction, the torque increases. The drilled samples are further subjected to mechanical testing. Tensile studies confirms that better mechanical properties are obtained for optimum machining parameter of (0.045 mm/rev, 210 rpm) for 3 wt% nanoclay and glass fiber-reinforced polyester nanocomposites. The hybrid clay and glass fiber-reinforced nanocomposites generally posses better mechanical properties compared with pristine glass fiber-reinforced polyester composites.

Thermodynamics equilibrium analysis on the chemical vapor deposition of HfC as coatings for ceramic matrix composites with HfClx(x?=?2–4)-CyHz(CH4, C2H4 and C3H6)-H2-Ar system

Juanli Deng*, Baofu Lu, Kaiyue Hu, Bohan Zheng, Shangwu Fan, Laifei Cheng, Litong Zhang

Advanced Composites and Hybrid Materials, 2018, 2: 102–114

DOI: 10.1007/s42114-018-0069-7

Abstract: A detailed thermodynamic equilibrium analysis in the chemical vapor deposition of HfC as coatings for ceramic matrix composites with HfClx(x = 2–4)-CyHz(CH4, C2H4and C3H6)-H2-Ar system has been investigated using the FactSage code. To protect the excellent performance of the composites, we demand a suitable composition and yield of condensed phases. They have been examined as functions of the inject reactant ratios of HfClx/(HfClx + CyHz) and H2/(HfClx + CyHz), temperatures, and pressures. The results show that the HfCl4 species are the optimal Hf-source in the deposition process. The ideal ratio parameters for production of single phase HfC are Log[H2/(HfCl4 + CyHz)] = 2 and Hf/C = 1. And the optimum temperature condition is above 1200 K. A lower pressure of 5 kPa is found to be more favorable for the deposition of a pure HfC phase. The co-deposition of HfC with C or Hf will be easily obtained by only controlling the ratios of HfCl4/(HfCl4 + CyHz) and H2/(HfCl4 + CyHz). The HfCl4-C3H6-H2 precursor system should be the best choice in the experiment due to a higher yield of HfC at the same deposition conditions. The results in this work will be helpful for the further experiment investigation under different deposition conditions and put forward a new idea in exploration of the preparation method of coatings for ceramic matrix composites.

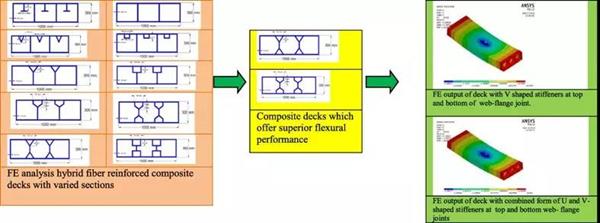

Characterization and structural performance of hybrid fiber-reinforced composite deck panels

R. Gopinath*, R. Poopathi, S.S. Saravanakumar

Advanced Composites and Hybrid Materials, 2018, 2: 115–124

DOI: 10.1007/s42114-019-00076-w

Abstract: This paper presents the experimental and analytical investigation on the behavior of hybrid fiber-reinforced composite deck made up of glass and jute fibers embedded in vinyl ester matrix. Finite element evaluation of the flexural performance of the composite decks was carried out using ANSYS, FE software. It was observed that analytical evaluation underestimates the value of deflection of deck panels 1 and 2 by 10.91% and 18.57%, respectively, when compared to the experimental results. However, the value of strain obtained by FEA is appreciably higher than that observed during the experiment. The analytical evaluation of deck panels was further extended to HYFRP and GFRP (glass fiber-reinforced polymer) decks with varied cross sections obtained by changing the location and shape of stiffeners. The specifications stipulated by Ohio Department of Transportation (ODOT), USA, for FRP decks were used for evaluating the performance of deck panels. The values of maximum deflection and strain experienced by the deck panels with stiffeners at the web-flange joint were found to be less than that of deck panels provided with stiffeners at the center of top flange of each cellular unit. Out of the various configurations examined, the performance of decks with V-shaped stiffeners and combination of U- and V-shaped stiffeners at top and bottom web-flange joint were found to be best with substantially lower deflection and strain.

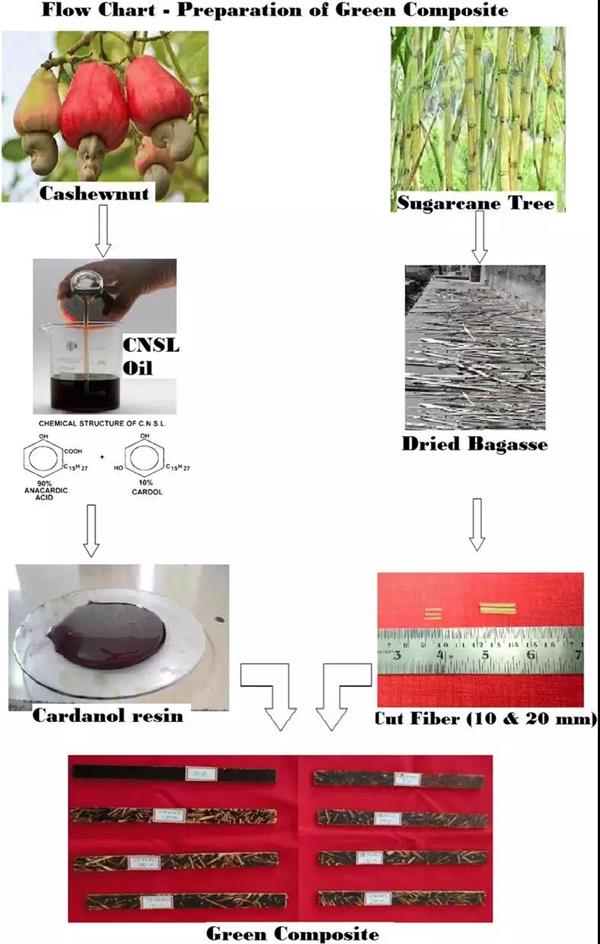

Comparative mechanical, thermal, and morphological study of untreated and NaOH-treated bagasse fiber-reinforced cardanol green composites

Comparative mechanical, thermal, and morphological study of untreated and NaOH-treated bagasse fiber-reinforced cardanol green composites

Balaji A*, Karthikeyan B, Swaminathan J

Advanced Composites and Hybrid Materials, 2018, 2: 125–132

DOI: 10.1007/s42114-019-00079-7

Abstract: In recent years, natural fibers are replaced by synthetic fibers as reinforcing agents to fabricate biocomposites. The present study is aimed to blend an abundantly available natural fiber with biopolymer to fabricate green biocomposite material. Four sets of cardanol-based biocomposites were prepared by incorporating bagasse fibers cut length 10 mm (chemically treated and untreated) and 20 mm (chemically treated and untreated) with biopolymer. These cut fibers were blended in various wt% (viz., 0, 5, 10, 15, and 20 wt%) with cardanol. The tensile strength and impact test were performed to study the mechanical properties of the developed composites. The morphological study in tensile fractured specimens was carried out using scanning electron microscopy (SEM). In addition to this, differential scanning calorimeter (DSC) tests were also carried out. The result proved that the morphologies of the composites have an improved bonding between the fiber and resin, leading to enhanced mechanical properties. Among the four sets, 15 wt% of 20 mm NaOH-treated fiber length composite has better mechanical properties like higher tensile strength, impact strength, and thermal stability than other wt% composites. SEM photograph also supports for the same biocomposite.

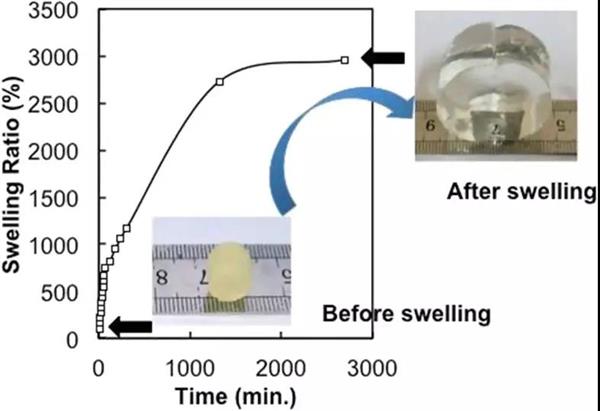

Synthesis and characterization of polyethylene oxide (PEO)—N,N-dimethylacrylamide (DMA) hydrogel by gamma radiation

Sadia Afroz, Fariha Afrose, A. K. M. M. Alam, Ruhul A. Khan, Md. Ashraful Alam*

Advanced Composites and Hybrid Materials, 2018, 2: 133–141

DOI: 10.1007/s42114-018-0058-x

Abstrac: tNovel polyethylene oxide (PEO)/N,N-dimethylacrylamide (DMA) blend hydrogel (PD hydrogel) has been prepared by applying gamma radiation on aqueous mixture of PEO and DMA. Different concentrations of DMA have been blended with aqueous solution of PEO and then gamma radiation of different doses was applied to form the hydrogels. The synthesized hydrogels were characterized using Fourier transform infrared-attenuated total reflection spectroscopy (FTIR-ATR) and scanning electron microscopy (SEM). The effect of different radiation doses, concentration of monomers on the properties of prepared hydrogel (PD hydrogel), such as gel content, swelling behavior, and mechanical properties (Tensile strength) was investigated thoroughly. Results showed that hydrogels were formed at the experimental conditions without the use of any external cross-linker. All the prepared hydrogels showed a significantly larger swelling ratio and improved mechanical strength.

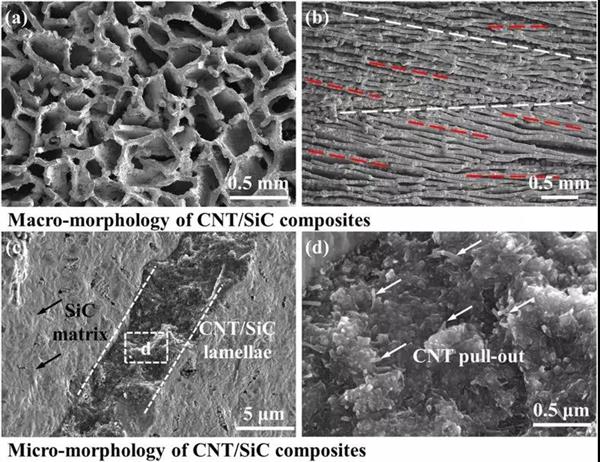

Macroscopic carbon nanotube assembly/silicon carbide matrix composites produced by gas phase route

Daoyang Han, Hui Mei*, Shanshan Xiao, Laifei Cheng

Advanced Composites and Hybrid Materials, 2018, 2: 142–150

DOI: 10.1007/s42114-018-0074-x

Abstract: Macroscopic carbon nanotube (CNT) self-assemblies are attractive in the field of high-performance composites for taking full advantage of outstanding physical and mechanical properties of individual CNTs at macroscopic level. In this study, macroscopic SiC ceramic matrix composites (CMCs) containing CNTs (CNT/SiC) based on the macroscopic CNT self-assemblies were fabricated using ice-segregation-induced self-assembly technique and chemical vapor infiltration process. The microstructure, macromechanical properties, electrical conductivity, and electromagnetic shielding effectiveness of the fabricated CNT/SiC composites were studied systematically.

One-step microwave synthesis of MoS2/MoO3@graphite nanocomposite as an excellent electrode material for supercapacitors

Yunrui Tian, Xing Yang, Amit Nautiyal, Yayun Zheng, Qingping Guo, Jujie Luo*, Xinyu Zhang*

Advanced Composites and Hybrid Materials, 2018, 2: 151–161

DOI: 10.1007/s42114-019-0075-4

Abstract: We introduce a facile one-step microwave solid-state approach to prepare novel MoS2/MoO3 @graphite nanocomposite that can be utilized as an electrode material for supercapacitors. The electrochemical properties of nanocomposite are evaluated by cyclic voltammetry, galvanostatic charge/discharge, and electrochemical impedance spectroscopy tests. The nanocomposite exhibits the highest specific capacitance of 268 F g?1 for 3500 cycles at a current density of 1 A g?1. The nanocomposite shows excellent cyclic stability of 283% (258 F g?1) for over 6000 cycles in 6 M KOH electrolyte. In addition, the microwave method, which is prospected to realize industrial application, can be applied to partial sulfurization.

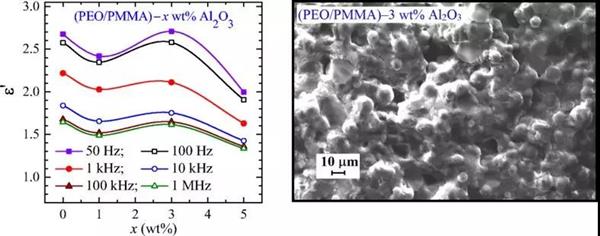

Investigation of alumina nanofiller impact on the structural and dielectric properties of PEO/PMMA blend matrix-based polymer nanocomposites

R. J. Sengwa*, Shobhna Choudhary, Priyanka Dhatarwal

Advanced Composites and Hybrid Materials, 2018, 2: 162–175

DOI: 10.1007/s42114-019-00078-8

Abstract: Polymer nanocomposite (PNC) films have been prepared by the solution-cast method using a polymer blend of poly(ethylene oxide) (PEO) and poly(methyl methacrylate) (PMMA) (PEO/PMMA = 50/50 wt%) as organic host matrix and x wt% Al2O3 nanoparticles (x = 0, 1, 3, and 5) as inorganic nanofiller. The morphological and structural behavior of these PNC films has been examined by employing the scanning electron microscope (SEM), X-ray diffractometer (XRD), and Fourier transform infrared (FTIR) spectrometer, whereas their dielectric polarization and relaxation processes are characterized by carrying out the dielectric relaxation spectroscopy (DRS) over the frequency range 2 × 101 to 1 × 106 Hz. Impact of Al2O3nanofiller on the spherulite and porous morphology, degree of crystallinity, polymer-polymer and polymer-nanoparticle interactions, complex dielectric permittivity, ac electrical conductivity, and the polymers structural dynamics has been explored. It is revealed that initially 1 wt% dispersion of Al2O3 in the PEO/PMMA blend matrix significantly reduces the crystallinity and dielectric permittivity, and hinders the cooperative chain segmental dynamics of the polymers which unevenly changes with the further increase of Al2O3 concentration up to 5 wt%. The dielectric and electrical parameters of these materials have also been compared with the PNC materials based on other polar polymer host matrices containing different oxide inorganic nanoparticles. The results of this work provide a guideline to design and fabricate the alumina nanoparticles loaded flexible-type polymer nanodielectric materials for advanced technologies.

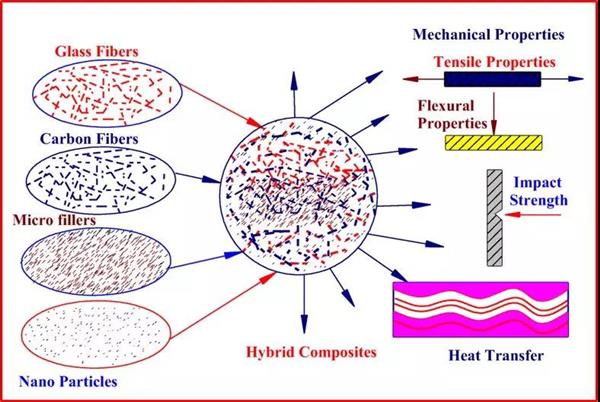

Combined effect of micro- and nano-fillers on mechanical, thermal, and morphological behavior of glass–carbon PA66/PTFE hybrid nano-composites

B. M. Rudresh*, B. N. Ravi Kumar, D. Madhu

Advanced Composites and Hybrid Materials, 2018, 2: 176–188

DOI: 10.1007/s42114-019-00089-5

Abstract: The combined effect of micro- and nano-fillers on mechanical, thermal, and morphological behavior of glass–carbon hybrid composite (GC) has been studied. Three material systems were selected for the study: hybrid glass–carbon fiber–reinforced 80 wt.% PA66–20 wt.% PTFE blend (GC), GC/micro-fillers (MoS2, SiC, Al2O3) (GCM), and GCM/nano-filler (Al2O3) (GCN). These composites were produced by the melt mix method using the extrusion technique followed by injection molding. It is found from the experimentation that the effect of micro-fillers impaired the mechanical behavior of micro-composites (GCM). The combined effect of micro- and nano-fillers slightly deteriorated the tensile and flexural behavior but improved the impact property of nano-composites (GCN). The synergistic effect between micro- and nano-fillers constrained the loss in strength of nano-composites at a higher temperature slightly exhibiting thermal stability. Further, it was observed from the morphological study through SEM photographs that the fractured surfaces were characterized by fiber fracture, severe deformation, and slight agglomeration of nano-particles in composite system.

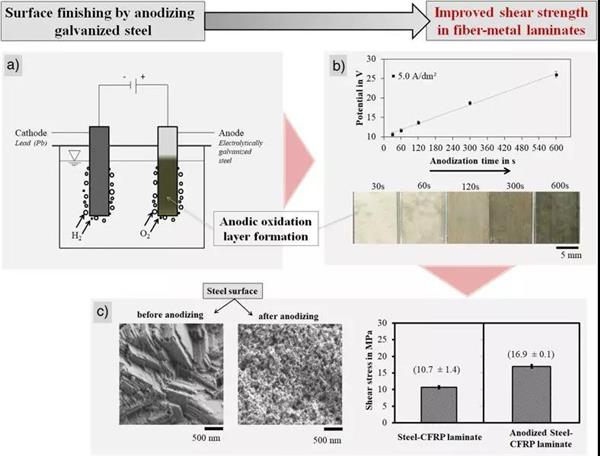

Anodizing of electrolytically galvanized steel surfaces for improved interface properties in fiber metal laminates

Katja Engelkemeier*, Christian Mücke, Kay Peter Hoyer, Mirko Schaper

Advanced Composites and Hybrid Materials, 2018, 2: 189–199

DOI: 10.1007/s42114-018-0071-0

Abstract: The adhesive properties in metal fiber laminates (FML) are essential regarding the bond strength of hybrid materials. The surface design of the metallic component has an important influence on the adhesive bonding. This work shows how the surface of electrolytically galvanized steel surfaces can be structured in a nanometer range by anodizing and how the adhesion properties in the FML can be significantly improved. To achieve this, homogeneous, reproducible nanoporous thin layers, in a range of 70 nm to 500 nm in thickness, were prepared in an anodization process of up to 10 min in a 0.2 M potassium hydroxide solution. In order to investigate the thin layer forming process as well as the wetting behavior, the current density was varied from 1 A/dm2 to 5 A/dm2 and the anodization time from 30 s to 600 s. For the wetting study, a drop shape analysis was carried out to provide information concerning the wetting behavior of the thin layers depending on the anodization parameters. Finally, shear tensile tests showed that the anodizing layer strengthens the interface in the FML, which results in an increased bond strength.