- Thermally stable poly-aromatic solid electrolyte coated polyethylene membrane as high-performance lithium-ion battery separator

- 来源:王建黎教授个人网站 2024-04-08

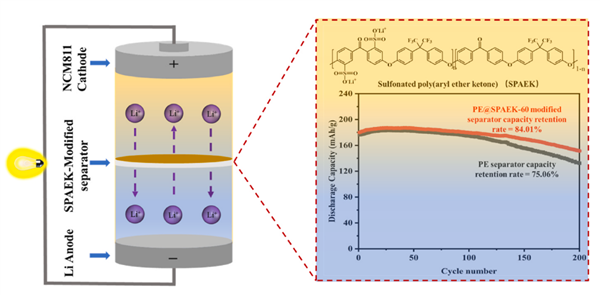

提高聚烯烃分离器的尺寸稳定性和电解质润湿性对提高动力锂离子电池的安全性和性能至关重要。在本研究中,通过在商用聚乙烯(PE)隔膜表面涂覆聚芳族固体电解质(磺化聚芳醚酮)(SPAEK),制备了显著提高热稳定性和溶剂润湿性的复合隔膜。有趣的是,磺化度为60%的SPAEK形成的涂层由于极性磺酸基导致相分离过程延迟,呈现出丰富的多孔结构。所述多电解质涂层使复合分离器具有超电解质亲和力和较高的电解质吸收量。此外,复合隔膜具有更好的综合性能,包括热稳定性和离子电导率。结果表明,spaek涂层复合隔膜组件的LiNi0.83Co0.11Mn0.06O2(NCM811)/Li 电池在2 C下的容量保持率为84.01%,循环200次后的比容量为151.25 mAh g-1。因此,这种改良的隔膜是一种潜在的材料,可以促进锂离子电池的高性能和安全性。

Improving the dimensional stability and electrolyte wettability of polyolefin separators is crucial to enhancing the safety and performance of power lithium-ion batteries (LIBs). In this work, composited separators that significantly improve both thermal stability and solvent wettability are prepared by coating polyaromatic solid electrolyte (sulfonated poly(aryl ether ketone), SPAEK) onto the surface of commercial polyethylene (PE) separators. Interestingly, the coating layer formed by SPAEK with a 60% sulfonation degree exhibits abundant porous structure owing to the polar sulfonic group inducing a retarded phase separation process. The polyelectrolyte coating layer enables both super-electrolyte affinity and higher electrolyte uptake of the composite separator. Moreover, the composited separator presents much better comprehensive properties, including thermal stability and ionic conductivity. As a result, the SPAEK-coated composite separator assembles LiNi0.83Co0.11Mn0.06O2 (NCM811)/Li battery exhibits a higher capacity retention rate of 84.01% at 2 C with a specific capacity of 151.25 mAh g-1 after 200 cycles. Hence, this modified separator is a potential material that facilitates high performance and safety for Li-ion batteries.

该工作由国家自然科学基金项目(22178317、22109138)资助。

https://doi.org/10.1016/j.jpowsour.2024.234355

- [来源:中国聚合物网]

- 了解更多请进入: 王建黎教授个人网站

- · Flexible chemical removing dissolved oxygen from water by nano-palladium hybrid microgel filled membrane

- · Bright and stable quantum confined CsPbBr3 nanocrystals through post-synthetic chemical cutting and in-situ encapsulation

- · Pickering Emulsion-Assisted Spherical Crystallization of Ibuprofen

- · Development of thermomorphic ionic liquids derivedfrom organophosphorus acids for homogeneousextraction processes